|

More super hard tools company

|

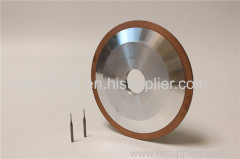

Rockwell hardness tester diamond indenter

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Rockwell diamond indenter or HRC diamond indenter for hardness testing machines

Diamond rockwell presser is a quality natural diamond with a specified weight.

It is used to measure the department's standard hardness tester and the material hardness test.

Hardness tester diamond head is a regulation of the weight of high quality diamond, welding inside the metal substrate, the cone shape of the grinding into a certain technical requirements, then through mechanical processing and become, is the key components of the hardness tester, varieties have diamond rockwell pressure head, vickers indenter, microscopic head, knoop pressure head, shore head, ultrasonic head, high temperature and pressure head and diamond stylus, etc.

Diamond rockwell head technical specification:

Model: the HRC - 3

Length: 25 mm

Angle: a = 120 ° R = 0.2 mm

Value: HRC height: 0 medium: 0 low: 0

Handle body: no. 6.36 x 10 no. 8 x 15 (steps) (approximate value)

Diamond indenter hardness tester is the main accessories, price concessions, can change at any time.Made of high quality natural diamond rockwell head, electric rockwell head, three with Dave 50 vickers pressure head, head, small head, knoop pressure head, shore head, standard fittings of pressure head is the key to all kinds of hardness tester.

Model: the HRC - 3

Length: 25 mm

High: + 0.3

Middle: + 0.2

Low: 0.1

Angle: a = 120 ° R = 0.2 mm

The handle body: 6.36 x 10 8 x 15 (steps)

Installation note:

1. Before the installation surface oil should be cleared away

2. When installation should guarantee the pressure head mounting surface by tight binding on the spindle end face

3. When the workpiece should be stable and reliable

4. Don't test points near the edge of a workpiece to prevent workpiece head damage security instability

5. It is strictly prohibited to hit head

Product features

pure natural primary diamond head;Level of accuracy and precision meet JJG334-93;Advanced welding technology, solid and durable;Measuring accuracy, high stability;Head for the high quality stainless steel handle, delicate appearance;

Rockwell diamond indentation method:

1) Visual inspection method: visually observe whether the diamond portion of Rockwell diamond indenter has obvious cracks, if it is measured, the Rockwell diamond indenter is damaged;

2) Using the nail test method: use the surface of the nail to gently rub against the apex angle of the Rockwell diamond indenter and rub it back and forth several times. If the surface of the nail is not deep, the Rockwell diamond indenter is good, and vice versa;

3) Use the instrument to magnify the observation method: use the optical projector or image measuring instrument and the tool microscope to enlarge the apex angle of the Rockwell diamond indenter by 10 or 20 times, and observe whether the apex angle of the Rockwell diamond indenter is still a complete 120 degree apex angle. If the apex angle of the Rockwell diamond indenter is cracked or blunt into a rounded corner, the Rockwell diamond indenter is damaged and needs to be replaced.

If the Rockwell diamond indenter is judged by the above three methods, it means that there is a problem inside the HR-150A Rockwell hardness tester, which needs to be sent to the factory for repair or professional repair.

Indenters For All Kinds of Hardness Tester

Indenter type | Initial Testing Force(N) | total test force (N) | Application | |

HRA | Diamond Indenter | 98.07 (10kg) | 588.4(60kg) | Hard alloy, carbide surface hardened steel, hardened thin steel |

HRD | 980.7(100kg) | Thin steel plate, surface hardened steel | ||

HRC | 1471(150kg) | Hardened steel, tempered steel, cold hard cast iron | ||

HRF | ball indenter φ1.5875mm (1/16 inch) | 588.4(60kg) | Cast iron, aluminum, magnesium alloy, bearing alloy, annealed copper alloy, thin soft steel plate, etc | |

HRB | 980.7(100kg) | Mild steel, aluminum alloy, copper alloy, malleable cast iron, annealed steel | ||

HRG | 1471(150kg) | Phosphorus bronze, beryllium bronze and malleable cast iron | ||

HRH | ball indenter φ3.175mm (1/8inch) | 588.4(60kg) | Aluminum, zinc, lead, etc | |

HRE | 980.7(100kg) | Bearing alloy, tin, hard plastic and other soft materials | ||

HRK | 1471(150kg) |